Strategies to remove CO2 from the atmosphere, and their potentials

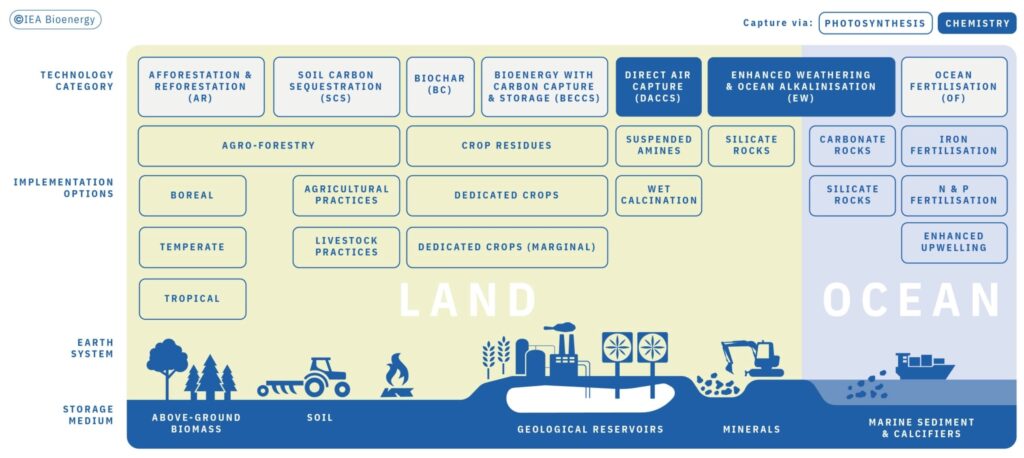

Sustainable Bioenergy and Bioenergy with Carbon Capture and Storage (BECCS) will likely be part of the technology portfolio used to reach net zero and net negative emissions

To reach ambitious climate mitigation targets, net GHG emissions need to fall to zero by the middle of the 21st century. Due to the delay in implementing mitigation measures and the persistence of GHG emissions, scientists are warning that emission reductions alone are likely to fall short of the Paris Agreement goals. Rather, we need to also ramp up CO2 removal technologies to reach net zero emissions by 2050 and from then on to create negative emissions to further reduce the CO2 concentration in the atmosphere. Bioenergy with Carbon Capture and Storage (BECCS) can play an important role in the CO2 removal technologies portfolio. BECCUS—Bioenergy with Carbon Capture, Utilisation, and/or Storage—could become an additional pathway that, although relying on similar technology, will not necessarily end up in negative

emissions.

CO2 (GHG) reduction is key. To achieve society’s ambitious climate targets, we need to massively reduce CO2 (GHG) emissions immediately. Bioenergy, coupled with carbon capture and sequestration (CCS), can actively remove CO2 from the atmosphere. (Photo credit: shutterstock/Vovan)

Global emission abatement

In 2015, nations at the Conference of the Parties in Paris agreed that global temperature increase should be limited to well below 2°C with efforts to limit global warming to 1.5°C. The subsequent Intergovernmental Panel on Climate Change’s Special Report on 1.5°C Global Warming assessed the knowledge on 1.5°C pathways.

It concluded that the Paris targets would require CO2 emissions to fall to 25–30 GtCO2eq/yr by 2030. What nations have put on the table in terms of emission reduction pledges would still lead to emissions of 52–58 GtCO2eq/yr in 2030, that is, almost twice the amount that would allow reaching the Paris targets, and far too much to achieve any 1.5°C pathway. Subsequent updates of the Nationally Determined Contributions in 2021, however, still appear to fall short of what is needed to get on track for 1.5°C. Not only would emissions need to hit net zero by the middle of the century; they would also have to transition to net negative thereafter, pulling CO2 removals into the spotlight.

The role of CO2 removals in emission reduction pathways

The IPCC’s Fifth Assessment Report already mentioned the need to remove CO2 from the atmosphere as one of the measures required to limit global warming to 2°C. The situation has since worsened and the contribution of CO2 removals (CDR) is vital if we are to achieve ambitious climate protection targets.

Scenarios are the primary tool used to delineate pathways to reach societally agreed targets at the science–policy interface. One example of climate pathways in line with the Paris Goals is provided by IRENA. In its 1.5°C scenario, the potential for CO2 capture per annum from processes that use biomass—to which CCS could in principle be applied—is around 10 Gt per year by 2050 across multiple sectors. The 1.5°C scenario assumes that BECCS captures and stores around 4.5 Gt per year of CO2 in 2050: less than half its potential. The largest opportunities are in power, heat, chemicals, and biorefineries; but BECCS could also be significant in cement, pulp and paper, and sugar production, and possibly also iron and steel production. BECCS, however, has not been currently validated in these industrial applications, and there are significant complexities to be addressed both regarding its deployment and whether it can be ensured as a sustainable biomass supply.

It has, however, become very clear that continued delays in implementing more stringent climate change mitigation measures and a more ambitious climate target are now making it impossible to achieve the already-ambitious Paris targets without CO2 removals (CDR).

There are some scenarios that explicitly try to exploit hitherto largely untapped mitigation potentials on the demand side. One example foresees a final 2050 energy demand of 245 EJ, which is significantly below current values and also lower than comparable scenarios in the mitigation literature. For example, the scenario with the lowest energy demand in the IPCC’s Fifth Assessment Report featured 274 EJ in 2050. Such a low energy demand scenario is thus unprecedented in the scenario literature, but, as the authors point out, it is not inconsistent with historical dynamics. As a result, such low energy demand scenarios manage to stay on a 1.5°C pathways without relying on Carbon Capture and Storage (CCS) and BECCS (bioenergy with CCS) for that matter.

Other studies have introduced a combination of otherwise less considered measures such as lifestyle changes, agricultural intensification, factory-cultivated meat, and lower population. The need for carbon dioxide removal (CDR) thus depends on how fast emissions are reduced in the coming decades; lifting higher mitigation potentials on the demand side can help to reduce that dependence to some extent. However, even those scenarios still need to remove about 100 Gt CO2 by 2100. Further delays in scaling CDR will mean jeopardising our ability to remove sufficient CO2 to maintain 1.5°C global warming.

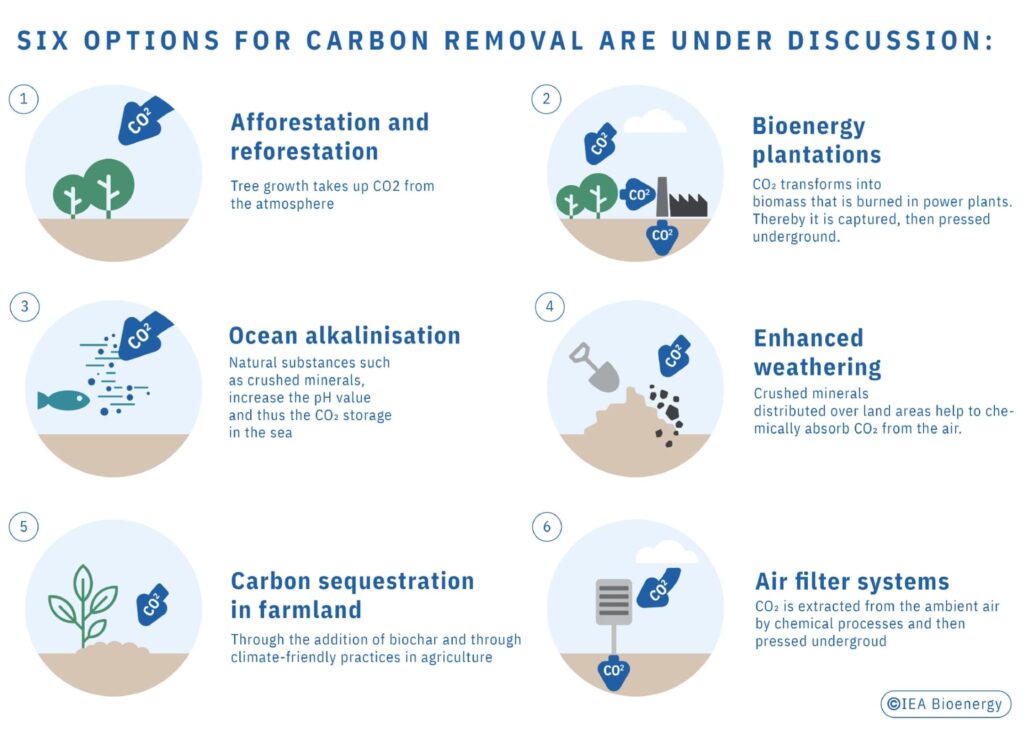

Strategies to remove CO2 and their potential

There are a number of ways to remove CO2 from the atmosphere. Those most prominently discussed rely on not allowing the emissions previously sequestered in biomass to escape to the atmosphere. In BECCS, systems energy is produced from biomass, and a substantial part of the emitted CO2 is captured and stored underground. The prevalence of BECCS in climate change mitigation pathways has come up against a wide range of sustainability concerns. Most of this

criticism is related to the question of the resulting land use change in the face of double-digit Gt removals and, indeed, the bottom-up literature conveys lower removal potentials compared to what some assume them to be. Yet, a number of techniques can be used to remove CO2 (and also other GHGs) from the atmosphere on a net basis. Clearly, all of them come with advantages and trade-offs.

BECCUS as an upcoming opportunity

Bioenergy combined with carbon capture and utilisation or storage, also known as bio-CCUS or BECCUS, is a concept that has been discussed in climate change mitigation research for quite some time. Only in the last five years, however, has the implementation of these technologies become the subject of serious consideration within governments and among private actors. The reasons for this are largely related to three factors: i) an emerging awareness of the need for BECCS and other negative emissions technologies if there is to be any chance of reaching for the Paris 1.5°C target; ii) rising CO2 prices; and iii) the rapidly decreasing costs of electricity generation from solar and wind (and expectations of similar developments for electrolysers) that have made BECCUS options based on power-to-X technologies more cost-effective.

In the light of this, identifying and implementing approaches to deploying and integrating BECCUS systems in ways that maximise benefits in terms of climate change mitigation—as well as in terms of energy system integration and sustainability ambitions more broadly—is extremely important.

Hence, several IEA Bioenergy Tasks (40, mainly with 36, 44, and 45) worked jointly from 2019 to 2021 on a project on the deployment of BECCUS value chains. The project focused on understanding the opportunities for, and obstacles to, deployment of BECCUS in different sectors. The aim was to try to cut across the full set of factors that determine successful deployment, from technology readiness, to business model viability, to design of policy and regulatory frameworks. Although some of the work is still in progress, results indicate that much of the technology required can, to a large extent, be considered proven.

The urgency of acting and scaling up CDR technologies to create negative emissions

- United Nations Climate Change, The Paris Agreement LINK accessed 18/02/2022

- IPCC (2018) Summary for Policymakers. In: Global Warming of 1.5°C. An IPCC Special Report on the impacts of global warming of 1.5°C above pre-industrial levels and related global greenhouse gas emission pathways, in the context of strengthening the global response to the threat of climate change, sustainable development, and efforts to eradicate poverty [Masson-Delmotte, V., P. Zhai, H.-O. Pörtner, D. Roberts, J. Skea, P.R. Shukla,A. Pirani, W. Moufouma-Okia, C. Péan, R. Pidcock, S. Connors, J.B.R. Matthews, Y. Chen, X. Zhou, M.I. Gomis,E. Lonnoy, T. Maycock, M. Tignor, and T. Waterfield (eds.)]. In Press.LINK accessed 18/02/2022

- Climate Action Tracker LINK accessed 18/02/2022

- Minx JC, Lamb WF et al. (2017) Negative emissions: Part 1 – research landscape and synthesis. Environmental Research Letters 13,063001. LINK

- IPCC, 2014: Climate Change 2014: Synthesis Report. Contribution of Working Groups I, II and III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change [Core Writing Team, R.K. Pachauri and L.A. Meyer (eds.)]. IPCC, Geneva, Switzerland, 151 pp LINK accessed 21/06/2022)

- IRENA (2021) Reaching zero with renewables, Capturing Carbon, Technical Paper 4/2021 LINK accessed 21/06/2022

- Grubler A, Wilson C et al. (2018) A low energy demand scenario for meeting the 1.5 °C target and sustainable development goals without negative emission technologies. Nature Energy 3, 515–527 LINK

- Fuss S, Lamb WF et al. (2018) Negative emissions – Part 2: Costs, potentials and side effects. Environmental Research Letters 13, 063002.LINK

- Jackson RB, Abernethy S et al. (2021) Atmospheric methane removal: a research agenda. Philosophical Transaction of the Royal Society A 379: 20200454. LINK

- Fuss S, Canadell JGet al. (2020). Moving toward Net-Zero Emissions Requires New Alliances for Carbon Dioxide Removal. One Earth 3(2),145-149. LINK

FURTHER READING

- Smith P, Adams J et al. (2019) Land- Management Options for Greenhouse Gas Removal and Their Impacts on Ecosystem Services and the Sustainable Development Goals. Annual Review of Environment and Resources 44 (1): 255- 286. LINK

- van Vuuren, DP, Stehfest E, et al. (2018) Alternative pathways to the 1.5 °C target reduce the need for negative emission technologies. Nature Clim Change 8, 391–397 LINK

- IPCC (2014). Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change. Edenhofer O, Pichs-Madruga R, Sokona Y, Farahani E, Kadner S, Seyboth K, et al., editors. Intergovernmental Panel on Climate Change. Cambridge, UK and New York, NY, USA: Cambridge University Press. LINK Accessed 22/06/2022

5 Reaping the multiple benefits of bioenergy

Synergies between energy, material, and food and feed services from biomass

Limited resources demand energy and material efficiency

Common sense, backed by scientific evidence, makes it obvious that our resources on planet Earth are limited. We will have to make most out of what we have, be able to reorganise not only the energy system but also the broader economy. The biosphere can still provide us with an undetermined diversity of solutions, if biomass is sustainably sourced and deployed according to ever-improving energy- and material-efficiency standards.

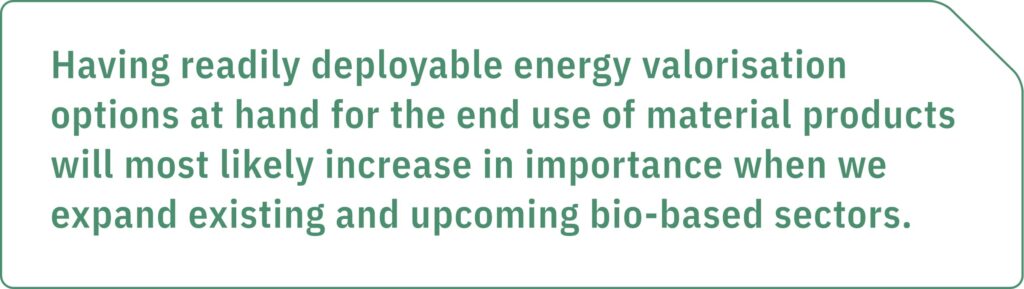

For the sake of resource efficiency, using, for example, high quality stem wood from sustainably managed forests for constructing building and furniture with a lifetime of several decades results in higher efficiency than producing consumables, such as recyclable paper or cardboard. The resource efficiency of material products is of higher importance than direct combustion for combined heat and power generation. Food crops from agriculture contribute more to society when consumed by humans than when converted to energy. There is, however, more to resource efficiency, as outlined in the following:

Stop landfilling biodegradable waste

Traditionally, the linear flow style of our current economy reflects a throwaway society and industry. Investments in efficiency have historically focused primarily on improving the input– output ratio of a main product, even though this might involve producing considerable amounts of waste. Reduction, reuse, and recycling of major products have, to date, been less of a priority. Some countries have acted on stemming the immense GHG emissions caused by landfilling biodegradable wastes; the uncontrollable release of methane from landfills (given that methane’s GHG warming potential is about 30 times more potent than that of CO2), fuels global warming and directly endangers communities living nearby. This landfilling of biodegradable waste, a highly material- and energy-inefficient practice, is often banned, particularly in Europe.

Meanwhile, anaerobic digestion of the more moist bio-waste and incineration of the drier fractions are widespread waste-treatment solutions, contributing simultaneously to the reduction of fossil fuels and power and/or heat provision, for example, in district heating, and also increasingly in the gas-grid. Even more important, industries have begun recognising the energy content of their residues as an economic added value: in Europe, for example, 83% of wood pellets used mainly for residential heating and combined heat and power are produced from sawdust, a saw-mill residue, while the rest comes mainly from wood reclaimed after material use.

Future products should be bio-based instead of fossil-based

In the next decades, more and more products will be bio-based. On the one hand, the broad product portfolio of fossil-based refineries including not only plastics, but also lubricants, solvents, fine chemicals and bitumen, will need to be replaced by bio-based counterparts. On the other, engineered wood products, carbon fibres, bio-based composites, and bioactive materials will extend our possibilities. The success of these emerging bio-based sectors will largely depend on how well biorefineries can handle different biomass resources and their residual fractions throughout the different process steps. Moreover, binding global treaties against plastic pollution (see UNEA 5.2) and other measures aiming to close circularity gaps will boost the significance of bio-based materials.

We define a “sustainable biorefinery” as the processing of biomass into a spectrum of marketable products (food, feed, materials, chemicals) and energy (fuels, power, heat), using a wide variety of conversion technologies in an integrated manner. Today, we are already able to convert a high variety of feedstocks from forestry, agriculture, and landscape management through a portfolio of technologies to platform feedstocks such as starch/sugar, vegetable oil, pyrolysis oil, lignin, and syngas and finally into all the types of chemicals and products currently needed. There is still, however, a wide range of biomass residues that cannot be collected and processed or recycled cost-economically today; this includes harvested algae from eutrophicated water bodies, post-consumer wood contaminated with paints or nails, and novel bio-based composite plastic products.

Look for the economic and environmental benefits of synergies

Synergies between bioenergy and other bio-based products include improved economic and environmental performances either via on-site co-production in biorefineries or in different sites and/or firms via entangled biomass supply networks. For example, sawmills processing stemwood to provide construction would create residues such as bark, wood chips, and sawdust. Using these residues for energy improves the economic and environmental performance of the sawmill. Similarly, food processing industries, including olive oil production, dairy, meat, and many others, produce considerable streams of biomass residues. Food processing residues can be converted to energy and in some cases biochemicals, improving the overall efficiency of the industry.

Our capability of converting biomass residues into non-energy products increases every day. Novel bioeconomy sectors, however, do not result in feedstock competition for bioenergy. Rather, and by way of example, the expected expansion in the production of bio-based insulation materials for building renovation will create considerable streams of new processing residues and post-consumer biomass. Cascadic use (cascadic principles) of biomass in a bioeconomy, together with landfilling restrictions, will create a broad feedstock base for bioenergy.

Other interesting challenges still remain; most technologies today rely on high quantities of biomass input of homogenous quality to leverage scaling effects. Pre-treating biomass to increase its homogeneity and commoditisation will improve its tradability. On the other hand, biorefineries may become more flexible, and allow for seasonal- and weather-dependent variations. Smaller- scale biorefineries are also being discussed as a means of producing required energy and materials at a community level (biorefinery communities).

When designing business models, the challenges involved in choosing the correct functional units and system boundaries in these non-linear business cases must be embraced so that the economic and environmental benefits are allocated correctly. Entrepreneurs should thus acknowledge the importance of tactical and strategic planning based on Life Cycle Analysis (LCA) and other science-based tools, such as Geographic Information System– (GIS-) based supply chain models.

- IPCC (2021): Summary for Policymakers. In: Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change [Masson-Delmotte, V., P. Zhai, A. Pirani, S.L. Connors, C. Péan, S. Berger, N. Caud, Y. Chen, L. Goldfarb, M.I. Gomis, M. Huang, K. Leitzell, E. Lonnoy, J.B.R. Matthews, T.K.Maycock, T. Waterfield, O. Yelekçi, R. Yu, and B. Zhou (eds.)]. In Press. LINK accessed 18/02/2022

- IEA Bioenergy Task 40 (2019) Margin potential for a long-term sustainable wood pellet supply chain LINK accessed 18/02/2022

- IEA Bioenergy Task 40 (2017) Global Wood Pellet Industry and Trade Study 2017 LINK accessed 18/02/2022

- Schipfer F, Kranzl L et al. (2017) Advanced biomaterials scenarios for the EU28 up to 2050 and their respective biomass demand. Biomass and Bioenergy 96,19-27 UNEP (2022 Fifth session of the United Nations Environment Assembly LINK accessed 22/06/2022

- UNEP (2022 Fifth session of the United Nations Environment Assembly LINK accessed 22/06/2022

- IEA Bioenergy Task 42 (2012) Bio-based Chemicals: Value Added Products from Biorefineries LINK accessed 18/02/2022

- IEA Bioenergy Task 42 (2020) Bio-Based Chemicals A 2020 Update LINK accessed 18/02/2022

- IEA Bioenergy Task 42 (2016) Cascading of woody biomass: definitions, policies and effects on international trade” LINK accessed 18/02/2022

- IEA Bioenergy (2016) Developing the Global Bioeconomy Technical, Market, and Environmental Lessons from Bioenerg LINK

- IEA Bioenergy Task 42 (2017) Wageningen University & Research Report: Small-scale biorefining LINK accessed 18/02/2022

- IEA Bioenergy Task 42 (2017) Wageningen University & Research Report: Small-scale biorefining LINK accessed 18/02/2022

- IEA Bioenergy Task 42 (2020) Technical, Economic and Environmental Assessment of Biorefinery Concepts Developing a practical approach for characterization LINK accessed 18/02/2022

- Sikkema R, Dallemand JF (2016) How can the ambitious goals for the EU’s future bioeconomy be supported by sustainable and efficient wood sourcing practices? Scandinavian Journal of Forest Research 32:7, 551-558 LINK

5 Reaping the multiple benefits of bioenergy

Bioenergy flexibility complementing variable renewable energies (VREs)

Sustainable bioenergy supports the integration of variable renewable energy sources such as photovoltaic and wind energy (Photo credit: pexels/Yaroslav Shurae)

We need to phase out fossil fuels

Flexibility is needed to enable higher PV and wind shares

Increasing periods of power over-supply and difficult-to-meet demand can be expected over the coming decades. Electricity prices will spread, which in turn will create market opportunities for novel and sustainable flexibility services, including battery storage, electric vehicle demand response, and also bioenergy.

The coupling of the power sector to heat and transport might cover short- to medium-term flexibility needs, if implementation of demand-side management is well adjusted to PV and wind expansion. Synthetic fuels from excess renewable electricity in combination with CO2 from biogas, as well as biomass gasification and combustion, can bring some relief in times of seasonal fluctuations. However, high synthetic fuel reliance comes with crucial risks regarding actual emission reductions, costs, supply security, and lock-in of fossil-fuel dependency.

In comparison to synthetic fuels, demand-side management, and sector coupling, bioenergy can provide long-term flexibility—and not only to the power grid. Intermediary bioenergy carriers such as wood pellets, chips, or bioliquids can be stored and flexibly converted into heat and power. In this way, bioenergy can complement, for example, heat from heat pumps or solar heat, especially in the winter months. Carbon dioxide from combustion or product gases from gasification or anaerobic digestion can be upgraded with hydrogen from variable renewable energy over-supply to biomethane, which can be transported and stored in the gas-grid.

Flexible bioenergy, in theory and in practice

The variety of bioenergy options supporting VRE integration extends over the entire biomass supply chain: “Feedstock flexibility” allows feedstocks to be switched depending on seasonal availability and quality, “Bioenergy carrier flexibility” addresses the possibility of storing energy in the form of biomass over longer periods to induce seasonal flexibility, and of trading it between regions, hence providing spatial flexibility; “Operational flexibility”, is achieved when varying loads of power or heat are provided on purpose to match demand patterns. “Product flexibility” addresses flexible switching between power-, heat-, and chemical-based production.

If one looks at the full catalogue, it is obvious that many technologies and their respective infrastructures are already in place or exhibit high readiness. Moreover, and in relation to other flexibility services, their importance for providing longer-term, seasonal flexibility is a unique feature. Finally, the possibilities for providing flexibility beyond energy, for negative emissions, and for the utilisation of carbon and materials are exceptional. Those flexible bioenergy services also include synergies with hydrogen production based on VREs. Anaerobic digestion and biogas

upgrading to biomethane co-produce particularly clean bio-based CO2 streams, which can and should be used to convert hydrogen into an easily tradable and storable energy carrier.

Flexible bioenergy options can significantly reduce GHG emissions from the energy system. In practice, however, sustainable flexibility services and remuneration for them are not yet widespread. Even more so, the implementation of flexible bioenergy is in its infancy, even in pioneer economies—for example, Germany with a flexibility premium for additional biogas storage capacities and Italy with a pilot program for Mixed Qualified Virtual Units programme for virtual agglomeration of bio- (and other) power production. Further market instruments and, in general, a better understanding of how to account for the added value of flexibility must still be developed.

A joint energy system, common challenges

Bioenergy flexibility can complement the system integration of high Variable Renewable Energy sources (VREs). However, dedicated frameworks are required, including market mechanisms and a deeper understanding of the benefits of flexibility. Respective technical, organisational, and social innovations have to be developed to allow for businesses to make economic profits from overall systemic benefits. Meanwhile, first projects will demonstrate the added value of flexible bioenergy on a business level, and their success stories need to be monitored, disseminated, and multiplied. On a systemic level, energy and economic modelling must outline its societal welfare

potential.

- IEA Bioenergy Task 44 (2021) Technologies for Flexible Bioenergy,LINK accessed 18/02/2022

- Dotzauer M, Oehmichen K et al. (2022) Empirical greenhouse gas assessment for flexible bioenergy in interaction with the German power sector, Renewable Energy, 181, 1100-1109, LINK

- IEA Bioenergy Task 44 (2021) Expectation and implementation of flexible bioenergy in different countriesLINK accessed 18/02/2022

- IEA Bioenergy Task 44, Best PracticesLINK accessed 22/06/2022

- IEA Bioenergy Task 44 Report (2021) Lange, N. Five Cornerstones to Unlock the Potential of Flexible Bioenergy. 2021, 8.LINK accessed 22/06/2022

- High-temperature industrial heat IEA (2021) Tracking Industry 2021,LINK accessed 22/06/2022

- IEA Bioenergy (2020). Bioenergy for High Temperature Heat in Industry (2020) Case Study 5: Wood chips combustion for process steam in a potato processing industry LINK accessed 18/02/2022

- IEA Bioenergy (2020). Bioenergy for High Temperature Heat in Industry (2020) Case Study 2: Gasification of paper reject to displace natural gas usage in a pulp and paper processLINK accessed 18/02/2022

- IEA Bioenergy (2020). Bioenergy for High Temperature Heat in Industry (2020) Case Study 3: Process steam in a dairy factory via fast pyrolysis bio-oilLINK accessed 18/02/2022

- IEA Bioenergy (2020). Bioenergy for High Temperature Heat in Industry (2020) Case Study 4: Waste-to-Energy for the production of steam for paper productionLINK accessed 18/02/2022

- IEA Bioenergy (2020). Bioenergy for High Temperature Heat in Industry (2020) Case Study 5: Combustion of wood chips and grain residues for process heat supply in the largest bakery in Switzerland (2021)LINK accessed 18/02/2022

- IEA Bioenergy (2020). Bioenergy for High Temperature Heat in Industry (2021) Decarbonizing industrial process heat: the role of biomassLINK accessed 22/06/2022

5 Reaping the multiple benefits of bioenergy

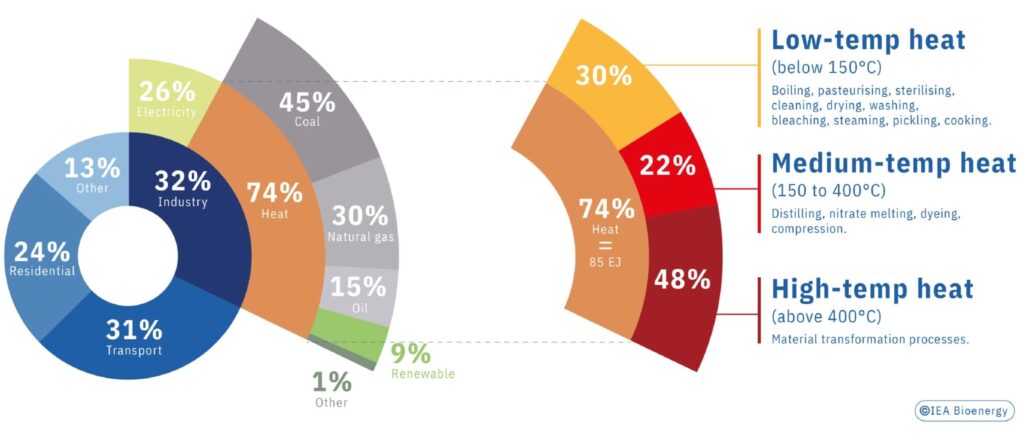

High-temperature industrial heat

Heat is by far the most important form of energy used in industry. The temperatures required by industrial processes are often far beyond 100°C which is the common upper temperature/heating range/limit in residential and commercial applications. Bioenergy technologies are capable of providing heat at a wide range of temperatures via different heat-transfer fluids, which makes bioenergy stand out among other sources of renewable heat. In 2020, the majority (86%) of renewable heat consumed in industry came from bioenergy, equalling 9.4% of the industrial heat demand.

Bioenergy can provide high-temperature heat for industry (Photo credit: istockphoto/Nostal6ie)

The replacement of fossil fuels from the industry sector is one of the major challenges the world is facing on its energy transformation path. The energy demand in industrial processes is dominated by high temperature heat applications where fossil fuels have particular advantages and electrification is often difficult. Bioenergy solutions are available to take over a relevant share of this demand. According to the IEA Net Zero by 2050 scenario, the use of biomass to produce heat in industry needs to double from 10EJ in 2020 to 20EJ in 2050.

Combustion of wood chips and composting residues for process steam generation in a potato processing industry

The first case study deals with process steam generation. Since 2015, the waste-processing company Attero has been operating a biomass-fired boiler that generates process steam for PEKA KROEF BV, a potato processing company near the village of Odiliapeel in the southern Netherlands.

Gasification of paper rejects to displace natural gas usage in a pulp and paper process

The case study on replacing natural gas with a paper reject gasifier is a good example of how industrial processes can be converted from fossil-based operation to partly bio-based operating processes. The Eska gasifier successfully managed to reduce natural gas usage and associated GHG emissions. The total waste produced for the site was also reduced, with waste being successfully turned into value.

For businesses using a large amount of natural gas to produce high temperature heat, this example shows how operations can be successfully managed when a switch to bio-based operations is made. It also shows that, overall, their emission profile has improved, which improves the marketability of their products.

Process steam in a dairy factory via fast pyrolysis bio-oil

This case study concerns the use of fast pyrolysis oil produced by Empyro in the industrial size steam boiler of FrieslandCampina (FC). A new natural gas fired boiler was designed and constructed to co-fire pyrolysis oil. In the boiler, process steam is produced (40 t/hr at 20 bar) for the milk powder drying process. The boiler normally operates with 70% of pyrolysis oil and 30% natural gas (heating value basis), but 100% back-up of natural gas is always available to guarantee a continuous steam supply to the core processes of FrieslandCampina. The Fast Pyrolysis Bio Oil (FPBO) is transported from Empyro (Hengelo) to FrieslandCampina (Borculo) by tank truck, a distance of about 30 km. A small on-site storage facility of about 100 m3 is available. The boiler was commissioned in late 2015 and until summer 2020 the use of FPBO has saved the company about 30 million m3 of natural gas and reduced their CO2 emissions by 60,000 metric tonnes.

Waste-to-energy for production of steam for paper production

To reduce its dependence on oil and fossil-based electric power, Nordic Paper decided to start their own energy production using municipal waste as fuel. The reason was mainly economic at a time of volatility in energy prices around 2005–2008. For this reason, Åmotfors Energi was founded with the main purpose of providing the paper mill, owned by Nordic Paper, with steam. The steam is used in the drying of the wet paper as the last step in the process. After a thorough investigation and feasibility study, the best alternative identified was to build a custom-made combined heat and power waste-to-energy plant.

Combustion of wood chips and grain residues for process heat supply in the largest bakery in Switzerland

The fifth case study deals with process heat supply in a bakery. The Coop Group is Switzerland’s largest retail company and Europe’s second largest wholesaler. Its production and distribution centre in Schafisheim incorporates a high-bay freezer warehouse and Switzerland’s largest bakery and confectioner with an annual production of 60,000 tonnes of baked goods. As a substitute for fossil fuels, a biomass combustion plant was built to produce energy process heat for the bakery using thermal oil. As the production of the raw materials for the bakery causes residues in the upstream milling process, the idea of using milling residues as energy for the bakery came up. To ensure the bakery operated flexibly, a concept was used which enables a variable energy production using 50% wood chips and 50% grain residues with the option of switching to 100% wood chips. Consequently, a combustion system was designed that enables the use of forestry wood chips from one silo to be mixed with pellets made from grain residues from a separate storage. The thermal oil boiler and the flue gas cleaning were adapted to comply with the challenges of the biomass fuel mix. To cover the rapid load changes of the bakery process, a gas-fired peak boiler complements the heat supply.

Policy synthesis report

A recently published policy synthesis report provides strategic information on market opportunities/potential and effective ways of addressing technical and non-technical barriers to implementing bioenergy-based process heat. The report builds on the lessons learned in the above cases, while providing a more generic analysis of the market potential and how its implementation can be supported, so as to unlock the enormous potential already mentioned above.

Understanding of the opportunities inherent in biomass-based approaches to providing industrial process requires a thorough analysis not only of the technological demands of the process itself, but also of local feedstock availability and how appropriate fuel logistics systems can be set up. Close collaboration between different supply chain actors and the establishment of long fuel supply contracts can often be key to providing the certainty needed to reduce investor risk. However, there are also key roles for policymakers in helping to fund not only R&D but also close- to-commercial demonstration facilities, as well as in creating demand, for example, through public procurement guidelines that incentivise low emission supply chains.

This policy report highlights the opportunities for bioenergy technologies to deliver heat in industry and compares it with alternatives for decarbonisation such as CCS, electrification, and hydrogen. Specific policy recommendations are provided to accelerate their adoption.

All reports produced during the Inter-Task-Project on bioenergy for high temperature heat in industry are available on the project website: itp- hightemperatureheat.ieabioenergy.com.

- IEA (2021) Tracking Industry 2021,LINK accessed 22/06/2022

- IEA Bioenergy (2020). Bioenergy for High Temperature Heat in Industry (2020) Case Study 5: Wood chips combustion for process steam in a potato processing industryLINK accessed 18/02/2022

- IEA Bioenergy (2020). Bioenergy for High Temperature Heat in Industry (2020) Case Study 2: Gasification of paper reject to displace natural gas usage in a pulp and paper processLINK accessed 18/02/2022

- IEA Bioenergy (2020). Bioenergy for High Temperature Heat in Industry (2020) Case Study 3: Process steam in a dairy factory via fast pyrolysis bio-oilLINK accessed 18/02/2022

- IEA Bioenergy (2020). Bioenergy for High Temperature Heat in Industry (2020) Case Study 4: Waste-to-Energy for the production of steam for paper productionLINK accessed 18/02/2022

- IEA Bioenergy (2020). Bioenergy for High Temperature Heat in Industry (2020) Case Study 5: Combustion of wood chips and grain residues for process heat supply in the largest bakery in Switzerland (2021) LINK accessed 18/02/2022

- IEA Bioenergy (2020). Bioenergy for High Temperature Heat in Industry (2021) Decarbonizing industrial process heat: the role of biomassLINK accessed 22/06/2022

5 Reaping the multiple benefits of bioenergy

Biofuels and long- distance transport—a perfect match

International shipping is responsible for transporting more than 80% of goods worldwide (Photo credit: Unsplash/

Ian Taylor)

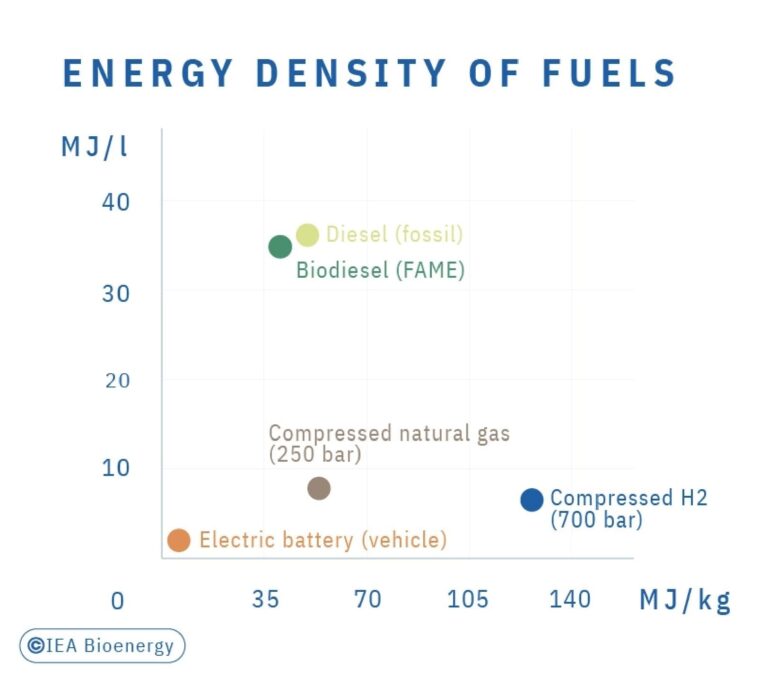

Biofuels have a specific role to play in long distance, heavy-duty transport. Carrying a battery of sufficient size to power ocean-going vessels, or storing hydrogen in sufficient amounts to provide the energy required for intercontinental flights is not imaginable today. Instead, the maritime, aviation, and long-haul trucking sectors are investigating the application of biofuels and other low carbon intensity fuels to fuel their large vehicles and vessels. Liquid biofuels have a volumetric and gravimetric energy density comparable to current liquid fossil fuels and can easily be stored on board; gaseous biofuels (biomethane) are either compressed or liquified to achieve higher energy density. When battery electric cars overtake combustion engines in the next decades, the focus area for biofuel applications will shift from road transport to aviation and shipping.

Aviation

The most popular long-distance people transport sector is the aviation sector. While only a small percentage of the world’s population has already been on an airplane, those that do fly tend to fly frequently, both for business and for leisure. The sector is predicted to steadily increase in terms of annual passenger-kilometres, yet has committed itself to carbon-neutral growth from 2019 onwards and to achieving net zero emissions by 2050.

The report “Decarbonising Air Transport” by the International Transport Forum (ITF) finds that alternative aircraft propulsion systems such as hybrid-electric aircrafts, all-electric aircrafts, and hydrogen-powered aircrafts are at low-to-medium technology readiness levels. Near-term GHG emission reductions will thus have to come from improved aircraft technology and operations and from the use of so-called lower carbon intensity sustainable aviation fuels (SAF).

These sustainable aviation fuels can be based on biomass or on e-fuels synthesised from hydrogen and carbon dioxide. A number of production pathways have already passed the very stringent and time- and resource-demanding process of the American Society for Testing and Materials (ASTM) certification; however HEFA-SPK (hydroprocessed esters and fatty acids– Synthetic Paraffinic Kerosene), based on fats and oils, currently provides the vast majority of biojet fuel. Hundreds of commercial flights are already operating on up to 50% blends of biojet fuels, demonstrating the technological maturity of flying on biofuels. The Global Framework for Aviation Alternative Fuels (GFAAF) of the International Civil Aviation Organisation (ICAO) visualises airports that receive regular or batch deliveries of SAF.

Shipping

Most of the world’s freight is transported by ship in huge ocean-going vessels. Until recently, they have mainly been operating on heavy fuel oil, which is a heavy fraction from oil processing that used to contain up to 3.5% sulphur and was very polluting. In 2020, a new limit on sulphur content came into force, limiting sulphur to 0.50% outside and to 0.10% inside designated emission control areas. Ships can comply either by using fuels that meet these sulphur limits or by installing exhaust gas cleaning systems (so-called scrubbers). Biofuels, electricity, hydrogen, synthetic hydrocarbons (including methanol), and ammonia appear to be the most promising options from the fuel side.

Other alternative shipping fuels that have been demonstrated include methane (preferably renewable), methanol, and LNG or LBG (liquified natural gas or liquified biogas); the use of electricity or hydrogen to date has been limited to smaller ships and ferries operating closer to the coastline. Ship owners are eager to purchase fuel- and powertrain-flexible ships, as the average lifetime of such vessels is 20 to 30 years, which is longer than the timeframe we can afford for burning fossil fuels. Maersk, the world ́s largest shipping firm, has, for example, announced that in the first quarter of 2024 they will introduce the first of eight new large ocean-going container vessels capable of being operated on carbon-neutral methanol. This is in response to ambitious targets for zero-carbon supply chains of over 100 large customers, with many more expected to follow.

Trucks

The road freight sector carries about two-thirds of on-land freight activity, measured in tonne- kilometres, and is the largest source of global diesel demand. It is important to reduce the sector’s dependence on fossil fuel, yet there are limited options available. “The Future of Trucks” report by the International Energy Agency (IEA) investigates four alternative fuels and powertrains: natural gas, biofuels, electric trucks, and hydrogen.

Natural gas can be used in so-called dual-fuel vehicles that use small volumes of diesel to ignite the natural gas. The (fossil) natural gas can also be replaced by biomethane to significantly reduce net well-to-wheel GHG emissions. The methane is stored on board the trucks either as compressed natural gas (CNG) or liquified natural gas (LNG). The deployment of natural gas trucks varies significantly across regions, depending on the availability of fuelling infrastructure and the price differential between natural gas and diesel. The provision of biomethane to refuelling stations is still rare.

Biofuel options for trucks include the well-established fuels biodiesel (FAME), renewable diesel (RD or HVO), and biomethane (from anaerobic digestion), as well as still to be fully developed options such as ED95 ethanol, BioSNG, bioDME, bio-Fischer-Tropsch diesel, and e-fuels. Biofuels can be used in the current truck fleet either neat or in blends with fossil diesel. Biodiesel is typically used as low-level blends with fossil diesel, for example, B7 with up to 7% biodiesel content in fleets; RD or HVO, although also suitable as neat fuel, are also often used as 30% blend to meet the diesel standard density requirements. Especially in Sweden, biomethane is used in municipal bus fleets and in trucks.

The need to carry a large and heavy battery to store the energy required for long-haul freight is a major barrier to the use of electric trucks. Development work is focusing on reducing the need to store electricity by supplying electricity while the truck is in motion. This can be done through electric road systems, such as overhead catenary lines and inductive power transfer. Such trucks and systems are currently in the pilot or early-deployment stage.

Fuel cell electric vehicles (FCEV) in general are still very rare (around 16,000 in total globally as of 2020), and FCEV truck pilots and demonstrations are even rarer. The storage of hydrogen to power a fuel cell for on-board power generation for the electric engine is 300 times more energy-dense (on a weight basis) than the storage of electricity in a lithium-ion battery. Yet, for the same driving range, hydrogen storage still requires four times more space than conventional diesel technology.

- IEA (2021) Net Zero by 2050 – A Roadmap for the Global Energy SectorLINK accessed 18/02/2022

- International Transport Forum, Decarbonising Air Transport – Acting Now for the Future International Transport Forum Policy Papers, No. 94, OECD Publishing, ParisLINK accessed 18/02/2022

- Airport Use of Sustainable Aviation Fuel MapLINK accessed 18/02/2022

- ICAO Environment, Offtake AgreementsLINK accessed 18/02/2022

- IMO International Maritime Organization 2020 – cutting sulphur oxide emissionsLINK accessed 18/02/2022

- Maersk eyes ‘leapfrog’ to carbon neutral fuels in shippingLINK accessed 18/02/2022

- IEA Report (2017) The Future of Trucks LINK accessed 18/02/2022

- STATISTA (2022 Projected fuel cell electric vehicle deployment worldwide between 2020 and 2030LINK accessed 18/02/2022