Biorefining

We can make use of the structural components of biomass —hemicellulose, cellulose, and lignin, as well as trace amounts of extractives and minerals. (Photo credit:Adobe stock/ jenyateua)

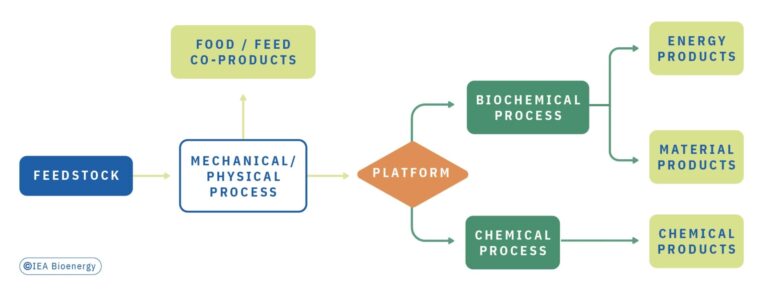

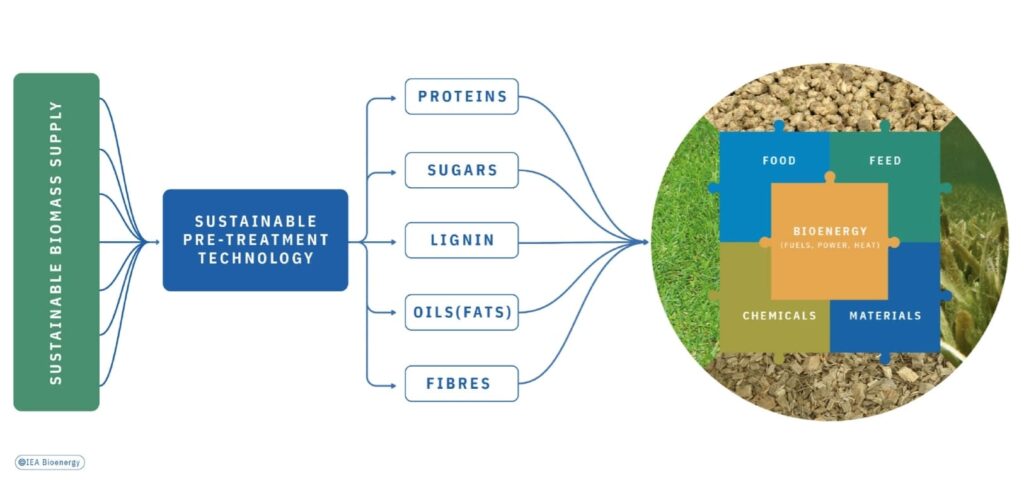

The diversity and complexity of biomass feedstocks offers both strengths and challenges. As almost “everything can be made from everything”, it is hard to identify the most promising combinations of feedstocks, processes, intermediates, and products. To shed light on this complex puzzle, experts of IEA Bioenergy Task 42 developed a biorefinery classification system and provided technical, economic, and environmental assessments for a range of biorefinery case studies to examine the status and opportunities of biorefineries focused on producing products for different market segments (chemicals, fibres, proteins, lignin). The classification system distinguishes among feedstocks, conversion processes, platforms (i.e., intermediate products), and products. Rather than producing a primary product and several co-products, a biorefinery produces one or more intermediate products (“platforms”) that are valorised through a spectrum of products.

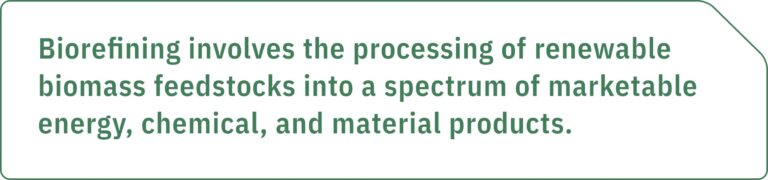

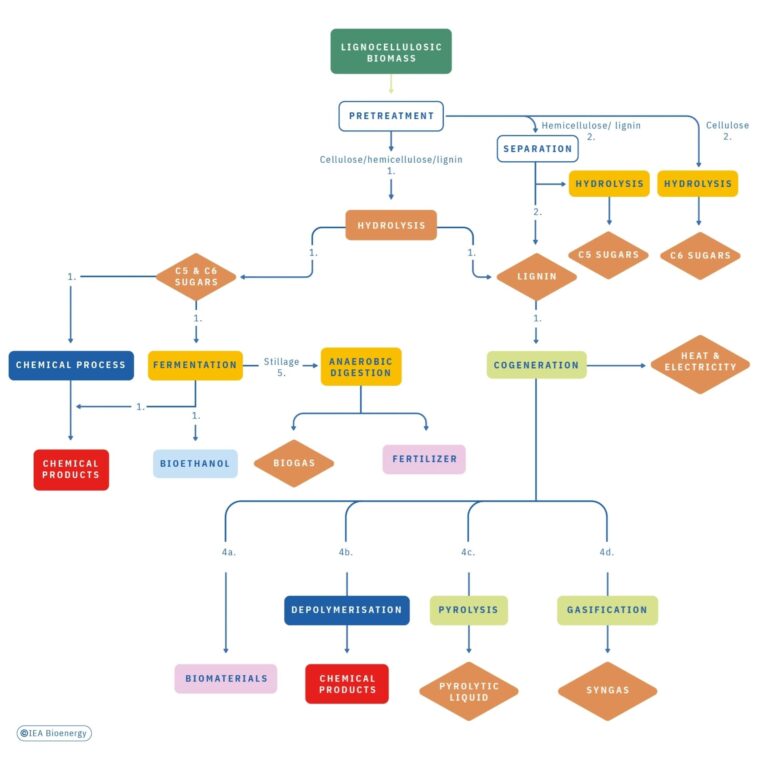

Within a biorefinery, the focus is on producing “platform chemical” intermediates such as pentose (C5) and hexose (C6) carbohydrates, syngas, lignin, or pyrolytic liquids, and on valorising these intermediates through a range of products, including energy carriers, chemicals, materials, and food and feed constituents. Biorefining involves the processing of renewable biomass feedstocks into a spectrum of marketable energy, chemical, and material products. Examples of biorefineries operational today include:

- Utilisation of C5 and C6 sugars from corn stover for the production of ethanol, electricity, and heat (lignocellulose biorefinery);

- Utilisation of C5 and C6 sugars from sugar beet or sugar cane to produce the biopolymer polyhydroxybutyrate (PHB) along with electricity and heat (sugar biorefinery);

- Utilisation of C5 and C6 sugars from food waste to produce polylactic acid (PLA) and animal feed (waste biorefinery);

- Utilisation of black liquor from wood chips for the production of pulp, lignin, and energy (lignocellulose biorefinery).

The terms in brackets indicate the classification of these concepts according to the classification standard VDI 6310 published by VDI, The Association of German Engineers.

Technology readiness level and status of implementation

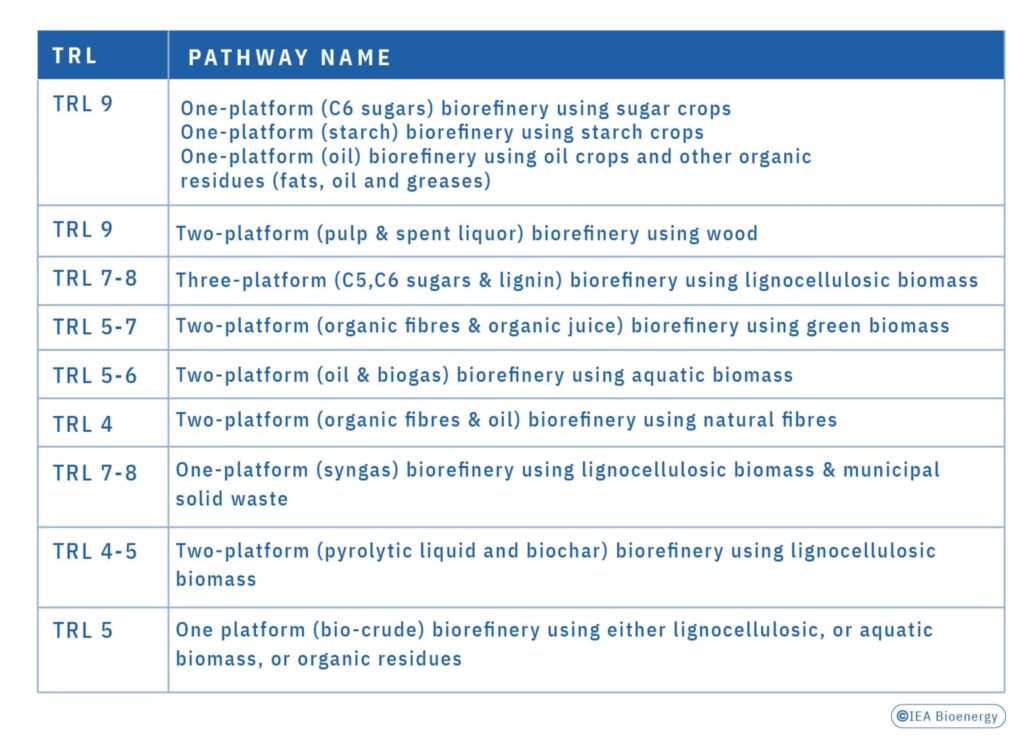

The technology readiness level (TRL) of biorefinery concepts is hard to define. The processes used are often already well established, but just not for the same feedstocks or product slates. Many companies that process biomass feedstocks have diversified into producing a range of products beyond their initial primary product(s); for example, integrated pulp and paper mills not only produce paper but also green electricity and district heat, as well as speciality chemical products, such as tall oil or methanol.

An overview of the current implementation status and outlook to 2030 of biorefineries in Europe is provided in “EU Biorefinery Outlook to 2030”. This study focuses on biorefineries primarily producing chemicals or materials—it does not include biorefineries whose major product is bioenergy or biofuel, nor does it include biorefineries focused on pulp and paper and board production. Within Europe, the study found over 400 biorefineries driven by chemicals or materials, more than half of which were utilising food and feed crop feedstocks. Facilities identified in the EU Biorefinery Outlook to 2030 project study are mapped in a database that is accessible here. IEA Bioenergy Task 42 recently launched its Global Biorefineries Atlas Portal which also includes biorefineries that primarily produce biofuels and other energy products; based on further information from the Joint Research Centre (JRC) of the European Union Research Centre (EURC), Bio-Based Industries (BBI), (U.S.) Department of Energy (DOE), and others, it allows users to create their own customised maps and download data. The Global Biorefineries Atlas Portal is accessible here.

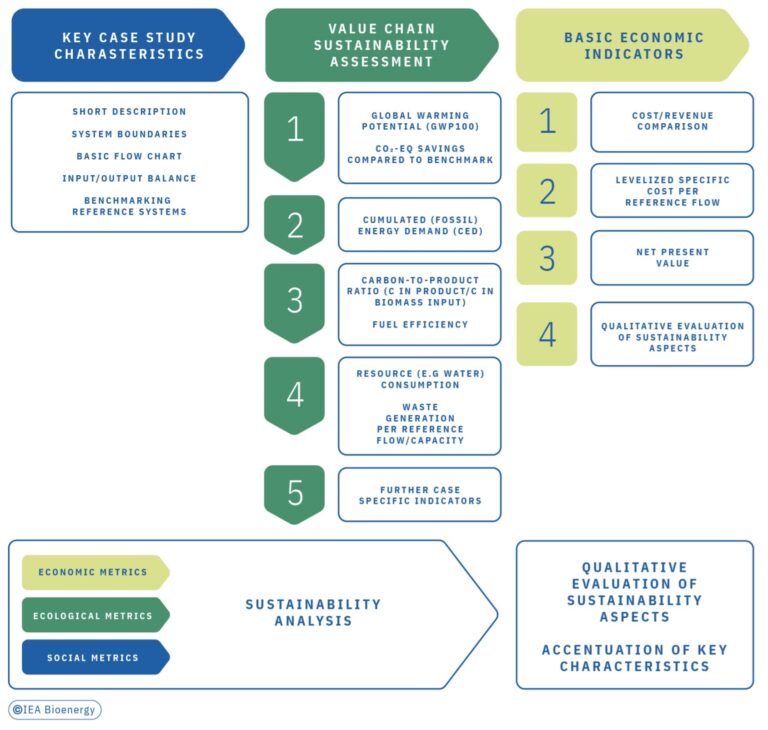

Technical, economic, and environmental (TEE) assessments

Experts of the IEA Bioenergy Task 42 have developed a methodology for making comparative technical, economic, and environmental assessments of biorefineries, conducting a series of case studies published as biorefinery fact sheets. The first four case studies, performed in 2019, showed that these biorefineries generated GHG emissions that were less than half of the fossil reference system, clearly indicating their benefits regarding global warming reduction. Feedstock costs were the main contributor to overall costs. Some cases struggled with economic feasibility based on simplified cost versus revenue comparison of an annual operation, as the fossil-derived products are on the market at lower prices.

Biorefinery production costs in general are expected to decrease through technological learning and by future biorefineries achieving greater economies of scale. For the moment, however, targeted supportive policy measures and programmes are required to drive the development.

The following biorefinery fact sheets, named according to the biorefinery classification system in which “platform” stands for “intermediate product” are available here:

- platform (C6 sugar, lipids) biorefinery to produce the biopolymer PLA and animal feed from food waste;

- platform (C5 and C6 sugars, lignin) biorefinery to produce bioethanol, electricity, and heat from corn stover;

- platform (C5 and C6 sugars, biogas) biorefinery to produce the biopolymer Polyhdydroxybutyrate

(PHB), electricity, and heat from sugar beet or sugar cane; - 1platform (black liquor) biorefinery to produce pulp, lignin, and energy from wood chips;

- 3-platform (C5 and C6 sugars, electricity and heat, lignin) biorefinery using wood chips for bioethanol, electricity, and phenols;

- 4-platform (biogas, green juice, green fibres, electricity and heat) biorefinery using grass silage and food residues for bioplastic, insulation material, fertiliser, and electricity;

- 3-platform (pyrolysis oil, syngas, electricity and heat) biorefinery using straw for FT-diesel and

methanol with oxygen gasification; - 2-platform (electricity and heat, syngas) biorefinery using wood chips for FT-diesel, FT-gasoline, heat, and waxes with steam gasification; and

- 3-platform (vacuum gas oil, pyrolysis oil, electricity and heat) biorefinery using wood for renewable gasoline and diesel, biochar, and pyrolysis oil.

Current research gaps and opportunities

Chemicals

Biobased chemicals could potentially be co-produced with secondary energy carriers in integrated biorefinery facilities. In 2010, Bozell and Petersen identified the following bio-based chemicals building blocks (or “2 platforms”) as being most promising for future development of biorefineries: succinic acid, furanics, hydroxypropionic acid/aldehyde, glycerol and derivatives, sorbitol, xylitol, levulinic acid, biohydrocarbons, lactic acid, and ethanol. When analysing the market potential for bulk chemicals from renewable sources, the BREW project found that under favourable market conditions the production of bulk chemicals from renewable resources could reach 113 million tonnes by 2050, representing 38% of all organic chemical production. Under more conservative market conditions, the market could still reach 26 million tonnes (17.5% of organic chemical production).

The biopolymers market volume was estimated to be 2.11 million tonnes globally in 2020 (bioplastics market data), representing only about 1% of global annual plastic production. Strong growth has been seen for polylactic acid (PLA), bio-based polypropylene (PP), and polyhydroxyalkanoate (PHA). Markets for biopolymers include flexible as well as rigid packaging, consumer goods, textiles, agriculture and horticulture, automotive and transport, building and construction, coatings and adhesives, and electrics and electronics.

Fibres

Applications for bio-based fibres are found in paper, fibre-based boards, textiles, composites, insulation materials for buildings, and in food and feed industries. Emerging market opportunities include the production and use of micro- and nano-fibrillated cellulosic materials for films, nanocomposites, coatings etc.; lightweight, high-performance materials for electric vehicles; carbon fibres from lignin; cellulose fibres for so-called fair fashion (see “Natural Fibres and Fibre-based Materials in Biorefineries” for details).

Proteins

Protein-rich biomass sources such as agricultural crops, crop residues, agricultural product processing residues, and post-consumer residues can be refined into marketable products for food, feed, and technical applications. While food applications and animal feed are the most important markets for proteins, they can also be used in technical applications such as coatings, adhesives, surface active agents, and as so-called green chemicals.

To increase the use of proteins for such products, research and development is still needed in several areas, for example, mild fractionation, separation/isolation and purification technologies, to allow protein-derived intermediates with the required functionalities to be produced.

Powerful policy instruments

The transition to a circular, bio-based global economy requires the establishment of strong, internationally aligned policies. The use of biomass for the production of foods, feeds, chemicals, materials, and bioenergy products will benefit from the following developments:

- Removal of subsidies on fossil fuels;

- High price for emitting net GHGs;

- Incentives for carbon capture and storage;

- Mandatory sustainability guidelines for forestry and agriculture;

- Mandatory circular economy–based production and reutilisation;

- Removal of restrictions on using sustainably sourced biomass feedstocks; and

- High social acceptance of the climate threat and the need for strong climate policy.

- IEA Bioenergy Task 42 (2019) Technical, Economic and Environmental Assessment of Biorefinery Concepts: Developing a practical approach for characterisation LINK accessed 18/02/2022

- IEA Bioenergy Task 42 Factsheets LINK accessed 18/02/2022

- IEA Bioenergy Task 42 (2020) Bio-Based Chemicals: A 2020 Update LINK accessed 18/02/2022

- IEA Bioenergy Task 42 (2018) Natural Fibers and Fiber-based Materials in Biorefineries Status Report 2018 LINK accessed 18/02/2022

- IEA Bioenergy Task 42 (2016) Proteins for Food, Feed and Biobased Applications: Biorefining of protein containing biomass LINK accessed 18/02/2022

- IEA Bioenergy Task 42 (2021) Sustainable Lignin Valorization LINK accessed 23/06/2022

- VDI 6310 (2016) Blatt 1 Klassifikation und Gütekriterien von Bioraffinerien LINK accessed 18/02/2022

- IEA Bioenergy Task 42 Biorefinery Fact Sheets LINK accessed 18/02/2022

- IEA Bioenergy Task 42 Factsheets LINK accessed 18/02/2022

- IEA Bioenergy Task 42 LINK accessed 18/02/2022

- Bozell JJ, Petersen (2010) GR Technology development for the production of biobased products from biorefinery carbohydrates—the US Department of Energy’s “Top 10” revisited” Green Chemistry 4 LINK accessed 23/06/2022

- Patel MK, Crank M et al. (2006) Medium and Long-term Opportunities and Risks of the Biotechnological Production of Bulk Chemicals from Renewable Resources, Utrecht University Repository LINK

- European Bioplastics, Bioplastics market data LINK accessed 18/02/2022

FURTHER READING

- IEA Bioenergy Task 42 (2016) Biorefining in a Circular Economy LINK accessed 18/02/2022